5-10T/H Chicken Feed Making Machine Price

5-10T/H chicken feed making machine price is generally between 70,000-300,000 USD. This type of equipment is mainly divided into broiler feed equipment and hen feed equipment.

The complete set of chicken feed equipment can not only be used in chicken feed factories, poultry feed factories, broiler feed factories, laying hen feed factories, but also in bird feed factories, duck feed factories, pig feed factories and other livestock and poultry feed factories.

5-15T/H chicken feed making machine refers to all the equipment needed to process chicken feed, not a single piece of equipment. Therefore, the so-called “chicken feed making machine price” refers to the price of a complete set of chicken feed equipment.

Generally speaking, chicken feed mill equipment can be used to process pellet feed, mash feed and crumbs feed. According to the type of feed, products such as complete compound feed, premix, and concentrated feed can be processed.

No matter what type of chicken feed you want to process, RICHI Machinery can design a complete process flow for you, provide a construction plan, and design, manufacture, install, and debug a complete chicken feed processing design. Of course, the chicken feed makermachine price must be different depending on the output and process requirements.

Main chicken feed making machine prices and Lists

If you want to know the chicken feed machine price, you must first know what equipment the chicken feed making machine includes:

Chicken feed making machines mainly includes chicken feed grinders, chicken feed mixers, chicken feed pellet machines, chicken feed coolers, chicken feed crumbler machines, grading screens, packaging scales, etc. In addition, auxiliary equipment includes boilers and bucket elevators. , screw conveyor, scraper conveyor, pulse dust collector, grease adding equipment, air compressor, laboratory equipment, etc.

Below are the main chicken feed processing machine prices and technical specifications:

chicken Feed Grinder machine

chicken feed making machine price: 1,000-35,000 USD

Capacity:

3-25 T/H

Main Power:

30-160 KW

chicken Feed Mixer machine

chicken feed maker machine price: 2,800-36,500 USD

Capacity:

250-2000 KG

Main Power:

4-55 KW

chicken Feed Pellet machine

chicken feed making machine price: 7,000-100,000 USD

Capacity:

1-48 T/H

Main Power:

22-315 KW

chicken Feed Extruder

chicken feed making machine price: 3,000-200,000 USD

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

Pellet Cooler Machine

chicken feed making machine price: 4,000-20,000 USD

Capacity:

3-25 T/H

Main Power:

30-160 KW

pellet crumbler machine

chicken feed making machine price: 2,000-20,000 USD

Capacity:

2-20 T/H

Roller:

2-3

vibrating screening machine

chicken feeds making machine price: 2,000-10,000 USD

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

chicken feed making machine price: 5,000-10,000 USD

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

- Crusher: First, the raw materials need to be crushed through a chicken feed grinder to achieve the required fineness for granulation. The degree of grinding is adjusted according to the feed needs of different chickens.

- Mixer: The crushed raw materials will be fed into the chicken feed mixer, where necessary additives (such as vitamins, minerals, premixes, etc.) are added and mixed evenly to ensure balanced feed nutrition.

- Batching scale: For occasions where the proportion of feed formula is accurately controlled, the batching scale is used to automatically measure various raw materials to ensure that the ratio is consistent every time.

- Chicken feed pellet machine: This is the core of the entire chicken feed making machine system. The raw material mixture is extruded through the die holes under high pressure to form uniform pellets. During the granulation process, the control of temperature and pressure is crucial to the hardness, density and molding quality of the granules.

- Cooler: The manufactured chicken feed pellets contain high moisture and temperature, and the cooler lowers their temperature to facilitate storage and prevent mildew.

- Grading screen: The cooled chicken pellets are screened through grading to select unqualified particles (too large, too small or crumbs) to ensure the quality of the finished product.

- Packaging machine: Finally, the qualified chicken feed pellets are sent to the automatic packaging machine for weighing and packaging for easy sales and transportation.

- Dust removal system: During the entire chicken feed production process, in order to keep the working environment clean and employees healthy, corresponding dust removal equipment will be equipped to collect dust during the production process.

- Conveying system: including various belt conveyors, screw conveyors, etc., used to connect various processes to achieve automated continuous production.

A complete set of 5-10t/h chicken feed machine can be customized and configured according to production scale, product type and user-specific needs, and is suitable for chicken feed processing plants and medium/large farms of corresponding sizes.

Whether you need to grind, condition, pellet, or cool, we can meet the demands of almost every conceivable application. Your entire chicken feed production process is covered from start to finish, and our rock-solid equipment lets you operate your chicken feed mill plant at the lowest possible cost. Our chicken feed making machines can handle anything you throw at them, so you can meet the demands of your customers.

Different output and configuration, different chicken feed making machine price

The output is different, and the design of the chicken feed production process is also different, so the chicken feed maker machine configuration must be different, and accordingly, the chicken feed machine price will be different.

Even if the output is the same, if the customer’s process requirements are different and the type of feed they want to process is different, the chicken feed machine cost will also be different.

5-7T/H chicken feed making machine price and configuration

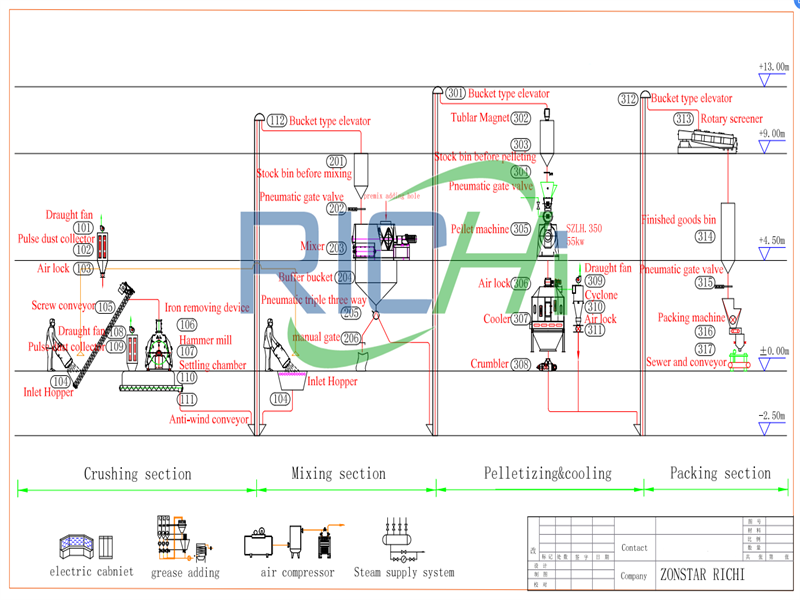

This is a design for 5-7T/H Chicken Mash and Pellet Feed Line. The characteristic of this design is that it adopts a horizontal design, without digging pits or breaking the roof, which reduces civil construction costs. And this design is suitable for the processing of three types of chicken feed: pellet feed, mash feed and crumbs feed. It can meet the needs of processing multiple feed types in one chicken poultry feed production line.

- Process design: Raw materials receiving&crushing section ——Mixing section——Pelletizing& Cooling & Screening& Packing section ——Electrical Control section

- Complete set chicken feed machine price: 100,000 USD

| Chicken feed making machine list | Model |

| Pulse dust collector | TBLMa.12B |

| Screw conveyor | TLSS20 |

| Iron removing device | Z-Type |

| chicken feed Hammer mill | SFSP.56*40 |

| Screw conveyor (Air locked) | TLSS20 |

| Bucket Elevator | TDTG36/18 |

| Storage bin | 1 m³ |

| Mixing machine (Pneumatic door) | SLHY.1 |

| Buffer bin | 1m³ |

| Permanent magnet drum | TCXT20 |

| Stainless Steel Conditioner | TZQ35X244 |

| Pellet machine for chcken feed | SZLH.350 |

| Cooling Machine for chcken feed | SKLN17*17 |

| chcken feed Crumbler | SSLG15*100 |

| Cyclone | SK800 |

| Rotary screener | SFJH100*2 |

| chcken feed Auto Packing machine | DSC-50 |

| Based on this 10t/h chicken feed process design, the configured chicken feed equipment also includes Feeding hopper with grids, Draught fan, Bucket elevator, Air lock, Settling chamber, Pneumatic two-way, Buffer bin, Belt and sewing machine, MCC Control Center ;Mimic control panel, Oil adding machine,Boiler system, Air compressor and srorage tank, etc. | |

10T/H chicken feed making machine price and configuration

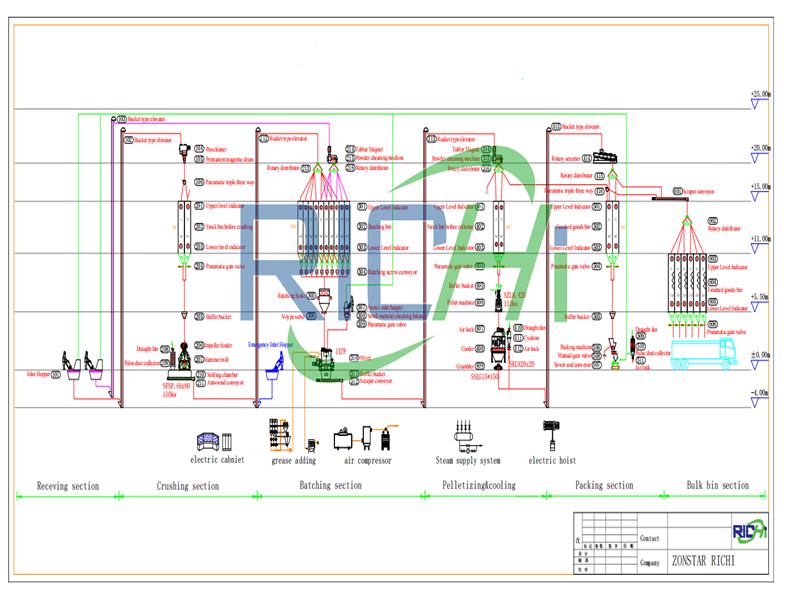

This is design of 10T/H Computer Batching Chicken Pellet Feed Line (With 60 TONS Storage Bins). The overall process of this production line design is very smooth, which can achieve high automation and continuous process. It is suitable for projects with high plant height and pit digging. The design is also equipped with a fully automatic packaging scale and bulk finished product warehouse to meet customers’ various finished product packaging needs.

- Process design: Bulk bin system——Materials receiving& pre-cleaning system——Crushing system——Batching& mixing system——Oil adding system——Pelletizing & cooling & screening system——Packing& dust collecting system

- Complete chicken feed machine price: 320,000 USD

| Chicken feed making machine list | Model |

| Drum type precleaner | SCY63 |

| Permanent magnetic sleeve | TCXT20 |

| Variable frequency feeder | SWLY20X80 |

| chcken feed Hammer mill | SFSP66*80 |

| Pulse dust collector | TBLMa.36A |

| Screw conveyor (air locked) | TLSS25 |

| Bucket Elevator | TDTG36/28 |

| Rotary distributor | TFPX8\TFPX6 |

| Powder precleaner | SCQZ60*50*100 |

| Batching scale | PLC1.0A |

| Single-shaft mixer | SLHJ2A |

| chcken feed Pellet machine | SZLH420 |

| 1-Layer Conditioner | TZ42*300 |

| chcken feed Cooling Machine | SKLN20x20 |

| chcken feed Crumbler | SSLG15*150 |

| Rotary screener | SFJH125*2C |

| Automatic Packing machine | DCS-50 |

| Based on this 10t/h chicken feed process design, the configured chicken feed equipment also includes Feeding hopper with grids, Draught fan, Bucket elevator, Air lock, Pre-Crushing bin, Pneumatic two-way, Buffer bin, Belt and sewing machine, Outlet Screw conveyor, Small material checking balance, Heating oil storage tank, Add oil line, Weight oil system, etc. | |

The above is just a brief list of the two 5-10t/h chicken poultry feed mill equipment configuration plans and prices that we have made, and these plans have been implemented in chicken feed projects in the United States and Thailand.

If you want to build your own chicken feed factory, contact us to customize your process plan and get chicken feed making machine prices and configuration plans.

Different project, different chicken feed making machine price

Each customer’s raw material formula, chicken feed products, process requirements and factory conditions are different, so the final process design and equipment configuration must be different. Different projects must have different configurations of equipment, so the final chicken feed making machine prices are also different. Let’s take a look at some featured 5-10t/h chicken feed plant projects.

15 t/h chicken feed making machine for sale Russia

- Feed Size:1-5mm pellets

- Construction Time: 6 months

- chicken feed making machine price: 1,350,600USD

- date: 2022.09.27

7-8T/H chicken feed making machine for sale Russia

- Feed Size: 2-4mm pellets

- Construction Time: 2 months

- chicken feed making machine price: 210,300 USD

- date: 2022.10.27

5-6 t/h chicken feed making machine for sale Kazakhstan

- Feed Size: 2-4mm pellets

- Construction Time: 2 months

- chicken feed mill machine price: 92,600 USD

- Date: 2022.12. 06

5-6T/H chicken feed making machine for sale Ethiopia

- Feed Size: powder feed

- Construction Time: 3 weeks

- chicken feed making machine price: 84,900 USD

- Date: 2019.11.06

6-10T/H chicken feed making machine commercial in Algeria

- Feed Size: 2-6mm pellets

- Construction Time: 8 months

- chicken feed making machine price:240,000 USD

- Date: Sep 31th, 2022

10-15T/H chicken feed mill plant in Uzbekistan

- Feed Size: 2-5mm pellets

- Construction Time: 1 year

- chicken broiler feed mill machine price: 390,000 USD

- Date: July 1th, 2023

5T/H poultry chicken feed making machine for sale Peru

- Feed Size: 3-6mm pellets

- Construction Time: 5 months

- chicken feed making machine price: 150,000 USD

- Date: February 2021

3-5T/H chicken feed making machine for sale uk

- Feed Size: 2-4mm pellets

- Construction Time: 4 Months

- chicken feed machine price: 60,000-65,000 USD

- Date: October 29, 2021

5 T/H chicken premix feed machine for sale El Salvador

- Feed Size: powder

- Construction Time: 6 months

- chicken feed machine cost: 480,000 USD

- date: 2022. 09.13

10 t/h chicken mash feed machine for sale Thailand

- Feed Size: powder

- Construction Time: 8 months

- hen feed making machine cost: 270,000 USD

- date: 2023. 07. 22

20-30T/H chicken feed making machine for sale argentina

- Feed Size: 2-6mm pellets & powder

- Construction Time: 14 months

- chicken feed machine cost: 660,000 USD

- Date: June 2023

35-40T/H broiler chicken feed making machine in Vietnam

- Feed Size: powder & 1.5-8mm pellets

- Construction Time: 9 months

- broiler hen feed plant cost: 950,000 USD

- Date: December 2023

1-2T/H poultry chicken food machine for sale Nigeria

- Feed Size:2-4mm pellets

- Construction Time: 30 days

- chicken feed making machine price: 39,000 USD

- Date: June 30, 2022

15T/H broiler chicken feed making machine for sale Afghanistan

- Feed Size: 2-8mm pellets

- Construction Time: 11 months

- chicken feed making machine price: 580,000 USD

- Date: December 2023

5-7 t/h machine for making chicken feed for sale Russia

- Feed Size: 2-10mm pellets

- Construction Time: 2 months

- chicken broiler feed making machine price: 97,160 USD

- date: 2022.06.09

chicken feed making machine 10 ton per hour in Uzbekistan

- Feed Size: 2-8mm pellets

- Construction Time: 7 months

- chicken feed making machine price: 460,000 USD

- Project date: 2023.09.13

5 t/h chicken feed making machine in kenya

- Feed Size: 2-10mm pellets

- Construction Time: 6 months

- chicken feed machine price: 184,500 USD

- Project date: 2021.10.11

10T/H chicken feed making machine in pakistan

- Feed Size: 1.5-6mm pellets

- Construction Time: 4 months

- chicken feed machine price: 451,820 USD

- Project date: 2022.10.14

8T/H chicken feed making machine in india

- Feed Size: 2-3mm pellets

- Construction Time: 9 months

- chicken feed machine price: 259,070 USD

- Project date: 2021.06.30

10T/H chicken feed making machine in south africa

- Feed Size: 2-10mm pellets

- Construction Time: 10 months

- chicken feed machine price: 350,000 USD

- Project date: 2021.05.10

What are the factors that affect the chicken feed making machine price?

Chicken feed making machine is a key piece of equipment in the field of chicken feed, and its performance and characteristics have a direct impact on the price. Before purchasing chicken feed making machine, it is crucial to understand the factors that affect its price.

The following are the key factors that customers should pay attention to when considering chicken feed making machine:

01 Power and output

The power and output are one of the factors that directly affect chicken feed making machine price. Higher power and greater throughput generally result in more expensive equipment. Customers need to select the appropriate power and processing capabilities based on their throughput needs to balance performance and cost.

02 Automation and control systems

Some chicken feed making machines are equipped with advanced automation and control systems that can improve operating efficiency and reduce manual intervention. These advanced systems often increase the chicken feed machine price. Customers need to weigh the degree of automation against their budget to choose a system that suits their needs.

03 Materials and build quality

The material and manufacturing quality are directly related to the durability and stability of the equipment. Quality materials and craftsmanship often mean more reliable performance, but can also result in a higher chicken feed machine cost.

High-quality materials often increase the cost of equipment, but also mean longer service life and lower maintenance costs. Customers should choose equipment that meets their needs and offers good durability.

04 Brand reputation and after-sales service

Choosing a well-known brand of chicken feed making machine is usually a wise choice. Brands with a good reputation usually provide more reliable products and excellent after-sales service. Customers can assess a brand’s credibility by studying its customer reviews, history, and after-sales service policies.

05 Additional features and customization options

Some chicken feed making machines may be equipped with various additional functions, such as dust prevention systems, screening systems, etc. Customization options may also affect chicken feed making machine price. Customers need to weigh the need for these additional features and options based on their actual needs and budget.

When purchasing a chicken feed making machine, customers need to comprehensively consider various factors to ensure that the equipment they choose meets their needs and is within their budget, power, equipment quality, degree of automation, manufacturing quality, brand reputation and additional features are all key factors that affect the chicken feed making machine price, and customers should make informed decisions based on these factors.

How to choose a high-quality chicken feed making machine manufacturer?

With the rapid development of the chicken feed market, the importance of chicken feed making machine as one of the core equipment in the feed manufacturing process is self-evident.

However, choosing the right chicken feed making machine supplier among many manufacturers is not easy. Chicken feed making machine price must be considered, but besides price, there are more important factors to consider.

Below, RICHI will introduce in detail how to choose a high-quality chicken feed making machine manufacturer to meet your production needs from aspects such as product quality, service support, customization capabilities, and technological innovation.

1. Product quality: Stability and reliability are the key

First of all, product quality is one of the key considerations when choosing a chicken feed making machine manufacturer. A high-quality chicken feed machine system should have stable and reliable performance to ensure efficient and safe operation during the production process.

When choosing a manufacturer, you can evaluate its product quality level by examining its product quality certification, historical cases, and customer feedback.

2. Service support: Pre-sales and after-sales are equally important

In addition to product quality, good service support cannot be ignored. High-quality manufacturers should provide a full range of service support, including pre-sales consultation, technical training, after-sales service, etc.

A responsible manufacturer will provide customers with timely and effective technical support and can provide customized chicken feed processing solutions according to customer needs.

3. Customization capabilities: Flexible to meet individual needs

In view of the different needs of different customers, the manufacturer’s customization capabilities are also one of the important considerations in selection. A high-quality manufacturer should have flexible customization capabilities and be able to carry out personalized customization according to the specific needs of customers, and tailor-made chicken feed making machines with strong applicability, efficiency and stability for customers.

4. Technological innovation: the driving force leading the development of the industry

Finally, technological innovation is also one of the important criteria for measuring the quality of manufacturers. Choosing a manufacturer with technological innovation capabilities means that you will be able to obtain a more advanced and efficient chicken feed making machine. Not only does this increase productivity, it also gives you a greater competitive advantage.

When choosing a chicken feed making machine manufacturer, product quality, service support, customization capabilities and technological innovation are key factors that need to be comprehensively considered.

Only by finding a supplier that has advantages in these aspects can we truly meet your production needs and help you stand out in the fierce market competition. I hope the above content can provide you with some reference and help when choosing a chicken feed making machine manufacturer. (Find RICHI on youtube)

get chicken feed making machine price

If you want to start a chicken feed processing business, if you want to purchase chicken feed equipment, feel free to contact RICHI Machinery to get chicken feed making machine prices and a full set of chicken feed process design plans and chicken poultry feed plant construction plans.